Model Year: 2015

Model: Series #3

Price: Call for pricing

Hours:

Options:

Additional Features:

Bennu Hydraulic Mast-Climbing Scaffolding Platform Series #3 Automatic Power Unit (APU) spec sheet (PDF)

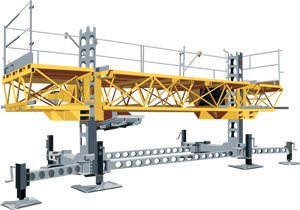

Bennu Hydraulic Mast-Climbing Scaffolding Platform Series #3 Automatic Power Unit (APU) spec sheet (PDF)Introducing the new continuous-climb series #3 self-leveling work platform.

- Galvanized Units Available

- Easy! Single Button Operation

- 20,000 lb. Capacity

- Important Safety Features:

1) Automatic Gearbox Brake

2) Spring-loaded Lock (Safety Dog)

3) Counter Balance Valve - Made in the USA

- Compatible with all Bennu Accessories

- Rentals or Sales: Financing Available

Since 2001, Jerry Castle & Son has carried parts for Series #1 and #2 from Bennu Innovations, Inc.

In 2005 when Bennu Parts & Service Inc., bought the rights to manufacture the parts and utilize the name, we remained a distributor.  Bennu Parts & Service has since created the Series #3 Continuous Climb scaffolding power units.

Bennu Parts & Service has since created the Series #3 Continuous Climb scaffolding power units.

Call us at 847-595-8444 or email us for any Bennu parts, including power units (new and used), towers, wings, wall-ties and many others.

Manuals, Specs, Bulletins

![]() Bennu Scaffolding Series 3 Operators Manual (PDF)

Bennu Scaffolding Series 3 Operators Manual (PDF)

![]() Bennu Scaffolding Series 3 Spec Sheet: Automatic Power Unit (APU) (PDF)

Bennu Scaffolding Series 3 Spec Sheet: Automatic Power Unit (APU) (PDF)

![]() Bennu Scaffolding Series 3 Spec Sheet: Modular Power Unit (MPU) (PDF)

Bennu Scaffolding Series 3 Spec Sheet: Modular Power Unit (MPU) (PDF)

![]() Bennu Scaffolding Series 3 Tech Bulletin: Adjusting Lifting Pressure (PDF)

Bennu Scaffolding Series 3 Tech Bulletin: Adjusting Lifting Pressure (PDF)

![]() Bennu Scaffolding Series 3 Tech Bulletin: Counterbalance Valve Pressure (PDF)

Bennu Scaffolding Series 3 Tech Bulletin: Counterbalance Valve Pressure (PDF)

![]() Bennu Scaffolding Series 2 Operators Manual (PDF)

Bennu Scaffolding Series 2 Operators Manual (PDF)

![]() Bennu Scaffolding Series 2 Safety Maintenance Checklist (PDF)

Bennu Scaffolding Series 2 Safety Maintenance Checklist (PDF)

![]() Bennu Scaffolding Series 2 Tech Bulletin: Hydraulic Control Connections (PDF)

Bennu Scaffolding Series 2 Tech Bulletin: Hydraulic Control Connections (PDF)

Parts Inventory

![]() Bennu Scaffolding Series 1 and 2 Parts List (PDF)

Bennu Scaffolding Series 1 and 2 Parts List (PDF)

Search our parts inventory

We maintain a large inventory of parts in stock. There are times when on-hand quantities change periodically so availability is subject to change.

We have experienced sales and service personnel ready to help you find your equipment and vehicle parts. Call 847-595-8444 or email us for more information.

Photographs

Photographs: Series #3 Automatic Power Unit (APU) PDF spec sheet

Photographs: Series #3 Modular Power Unit (MPU) PDF spec sheet

Photographs: Series #2 Galvanized Platforms

Photographs: Jobsites

- Chicago Jobsites

- Chicago Suburban Jobsites

- Chicago, Illinois – Northeastern Illinois University project

- Burr Ridge, Illinois

- Evanston, Illinois

- Joliet, Illinois

- LaSalle, Illinois

- New Lenox, Illinois

- Oak Park, Illinois

- Phoenix, Illinois – Coolidge School project

- Schaumburg, Illinois – YMCA project

- Skokie, Illinois

- Woodridge, Illinois

Chicago, Illinois – Northeastern Illinois University project

Phoenix, Illinois – Coolidge School project

Schaumburg, Illinois – YMCA project

Videos

2015 World of Concrete / World of Masonry

by Masonry Magazine, March 2015.

The Masonry Magazine crew headed to sunny and warm Las Vegas in early-February to attend one of the construction industry’s biggest business events and week-long parties, World of Concrete/World of Masonry. The event drew 55,779 registered professionals and featured more than 1, 459 exhibitors across more than 675,000 net square feet of space. Our minds were blown by the continued innovation across the masonry construction industry. Throughout the week, we also attended the many educational and fun events during the MCAA Annual Convention (see coverage on pp. 14 – 18 of this issue). Following are a few highlights from an eventful week during World of Concrete/World of Masonry.

2018 World of Concrete

Bennu Parts & Service will be at the World of Concrete, January 22-26, 2018.

Bennu Parts & Service will be at the World of Concrete, January 22-26, 2018.Come visit our outdoor booth #B51331 exhibit.

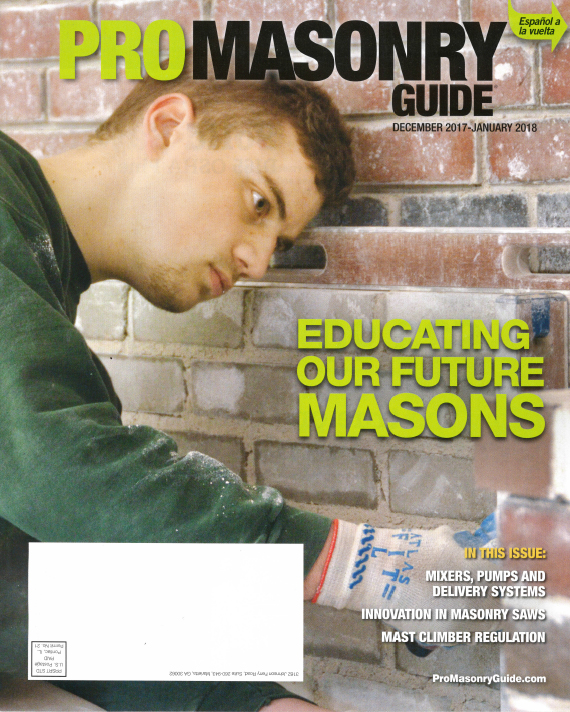

2017 Pro Masonry Guide Magazine

4 Things to Consider for Continuous Climbers

4 Things to Consider for Continuous Climbers

By Jennifer Morrell — Executive Editor, Pro Masonry Guide.

Whether you are using a mast climber, continuous climber or telehandler, you should be aware of safety aspects that come along with the job. To learn more about the correct usage and safety considerations of continuous climbers, Pro Masonry Guide sat down with Jerry Castle, president and owner of Elk Grove Village, Illinois-based Bennu Parts and Service. Following is what he had to say.

Whether you are using a mast climber, continuous climber or telehandler, you should be aware of safety aspects that come along with the job. To learn more about the correct usage and safety considerations of continuous climbers, Pro Masonry Guide sat down with Jerry Castle, president and owner of Elk Grove Village, Illinois-based Bennu Parts and Service. Following is what he had to say.

PMG: How do you approach training with your customers?

Castle: We provide a PowerPoint visual presentation along with a reference manual for the customer to follow along. We also have equipment on site for a hands-on demonstration. With a power unit on site, we can identify the points we are making in real time. We send a qualified trainer out to the client’s place of business to show them how to set up our equipment and to go over all of the details of what they’ve bought. If a person hasn’t had Bennu scaffolding training, we provide it, including the proper use of smart bars and wall ties hooked up to the tower to show where and how they function.

PMG: The Hispanic community is a significant part of the masonry labor force. How do you handle communication and/or the language barrier?

Castle: We ensure that we provide bilingual speakers and allow for translation when needed. Even if it makes the session go longer, we allow more time to accommodate our Spanish-speaking customers who do not speak English fluently.

PMG: Where do you see weaknesses regarding continuous climber safety and regulations?

Castle: During our training, we encourage a commitment of ongoing safety and training. Some people who have entered the workforce more recently may not be trained for the jobsite, so we do our part to emphasize to the owner the safe use of equipment and accessories. Safety first, the owner and workers must be reminded of it. The accessories we provide for scaffolding are developed to allow a safer approach.

PMG: What makes your continuous climber product different?

Castle: We have three important safety features in our scaffolding drive system. Our advanced design features a planetary gear box with a hydraulic disc brake and motor with a climbing wheel which rolls smoothly up the mast and onto each step. In between those we have a spring-loaded safety locking system (“Safety Dog”) that is always in operation and a counterbalance valve that will lock the hydraulics and prevent any movement, if a hose were to break. The scaffolding platform is self-leveling and ascends level at full climbing speed with synchronization during the elevation, a unique feature that took many years to develop and several engineers to perfect the design.